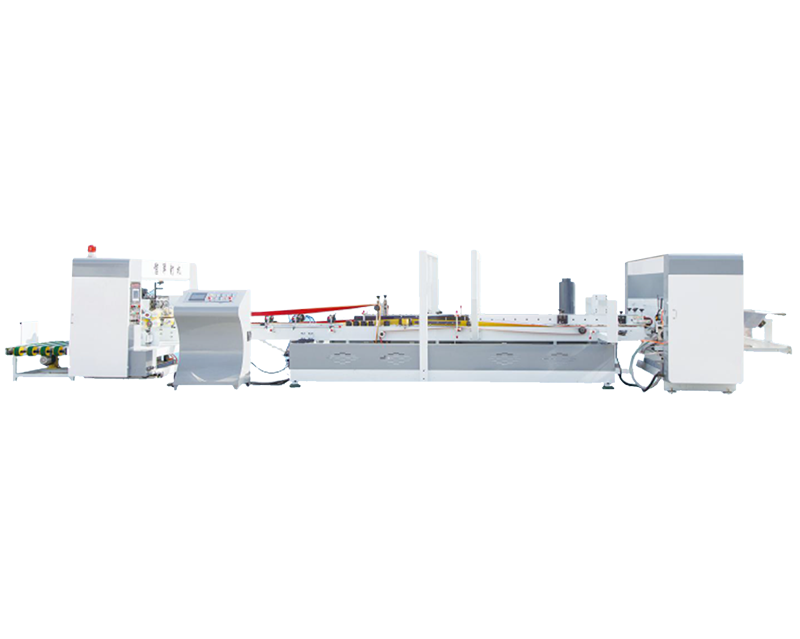

Full-automatic box-gluing machine

- Commodity name: Full-automatic box-gluing machine

- Product Description

-

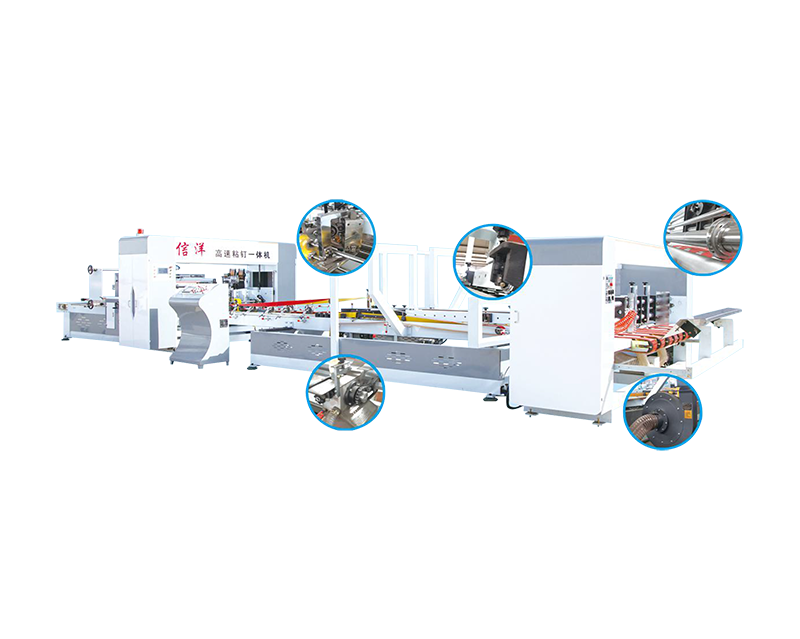

Product Features

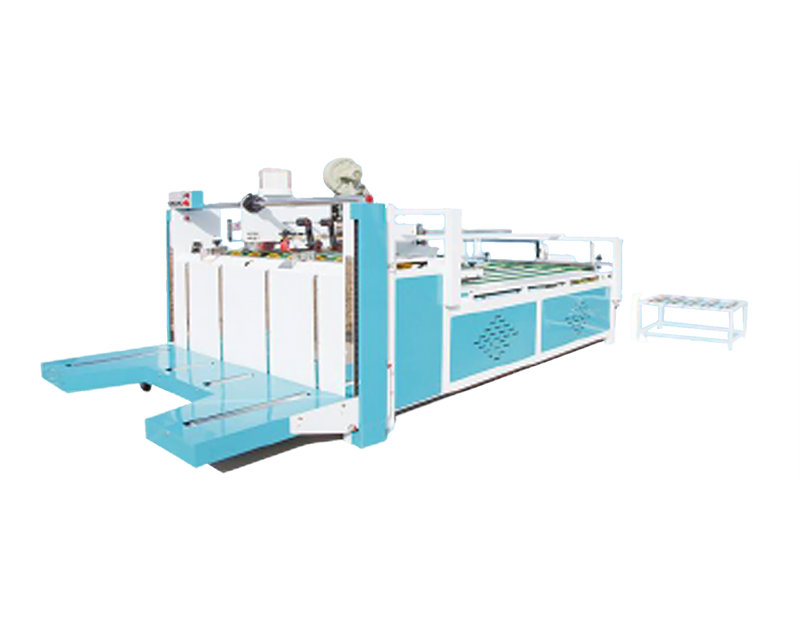

Paper feeding and gluing department

A. high friction belt suction paper feeding way, accurate and reliable, better adapt to the curve of cardboard processing.

B. Adopt high-end electromagnetic clutch and electromagnetic braking system, which can independently control the paper feeding part.

C. paper feeding, origami section linkage frequency conversion speed regulation, can change the speed according to customer requirements.

D. stainless steel glue wheel, glue evenly, glue size adjustable, never rust, has a strong corrosion resistance.

E. diaphragm pump glue, excess glue back to the glue bucket, not waste.

F. has the function of automatic alignment, neat cardboard, is conducive to the cardboard conveying correction.

G. the paper feeding part has a pre-pressing wheel, which is linked with the folding part and plays a great role in correcting cardboard with poor or even no pressing line.

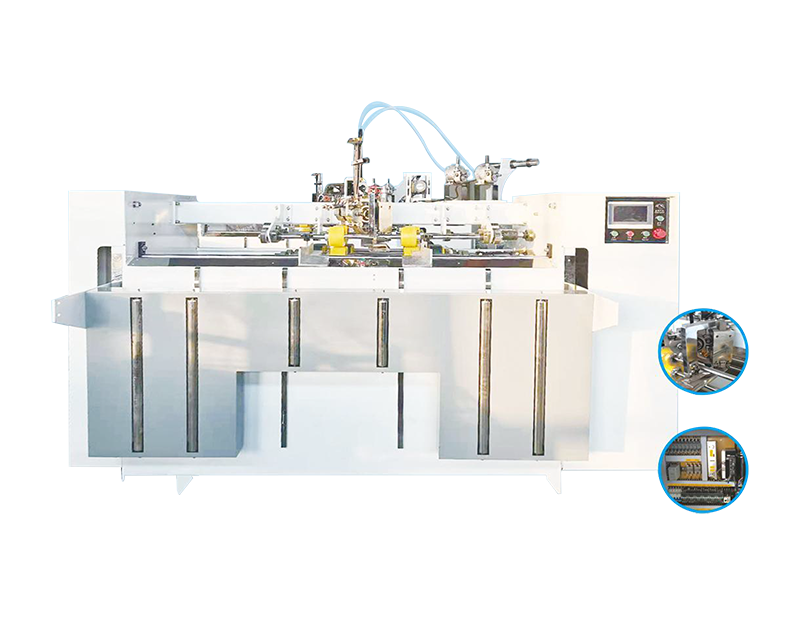

Automatic folding part

a. The conveyor belt adopts round seamless high friction belt imported from Germany to ensure the accuracy of cardboard conveying.

B. The folding part is equipped with two pressure line correction devices. For cardboard with poor pressure line, further correction is made during the folding process. It is simple and efficient, completely put an end to the "scissors mouth" (I. e., the upper and lower surfaces of the carton are not uniform after bonding, and one side of the mouth is large and the other side is small), and is suitable for cardboard with different corrugated thicknesses.

c. The high-end linear guide, brake motor and linear bearing are used together to make the machine adjust quickly and accurately, with low error and durability.

Counting stacking shaping section

a. The unique correction part of this machine has a unique and advanced coaxial asynchronous device, which achieves good correction correction of each cardboard and eliminates the scissors mouth.

B. PLC programmable controller and touch screen, remote control, rapid response, accurate action, easy operation.

c. Accurate counting, pneumatic push, belt transmission, high efficiency, good effect.

d. The carton output part adopts a slow stop conveying device, which can accommodate more than 200 cartons, and the cardboard boxes can be in a pressing state for a long time. It not only ensures the adhesive strength required by the carton, but also effectively improves the compressive strength of the carton, making the appearance of the carton more solid and beautiful.

Technical parameters

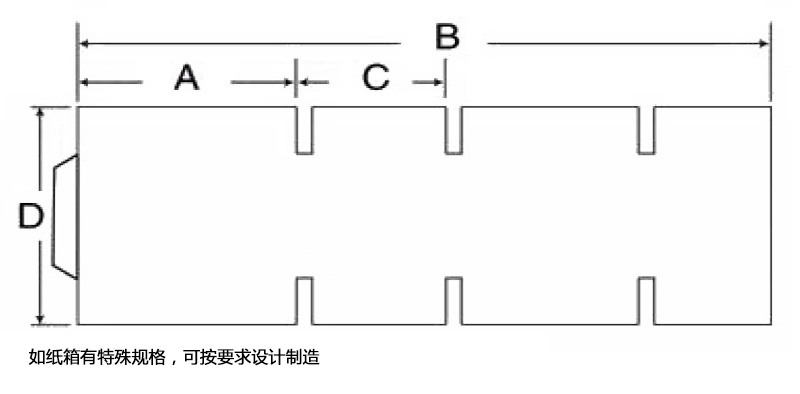

Model Xy-2800 Xy-3000 A 130-880 130-880 B 420-2400 420-2600 C 70-840 70-840 D 160-1200 160-1200 Work area 4000 × 15000 4000 × 15000 Motor power 13kw 13kw

Contact information:

WeChat/Tel:+86-15233175111

WeChat/Tel:+86-15532830120

Address: Wharf Economic Development Zone, Fucheng County, Hengshui City, Hebei Province

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!